Project Synopsis

Manage a pilot plant study of the evaporation and flaking of NaHS liquor for the production of concentrated flake for a new commercial scale plant.Project Summary

NaHS PRODUCT EVAPORATION AND FLAKING PILOT PLANT TESTING MANAGEMENT

The client wishes to build a new antimony refining facility. This facility will include a sodium hydrosulfide (NaHS) production area that will produce either 41% NaHS liquor or 71% NaHS flake from an H2S byproduct stream. Process Engineering Associates, LLC (PROCESS) was contracted by the client to manage an extensive pilot plant study of the evaporation and flaking of 41% NaHS liquor for the production of 71% flake, a process that has not been widely attempted on a commercial scale. It was PROCESS’ strong recommendation to the client that pilot testing be conducted prior to design of the evaporator and flaker. PROCESS’ project tasks included:

- Identification of a suitable pilot plant facility

- Preparation of detailed pilot testing plan

- Performance of on-site technical supervision of the pilot plant runs

- Preparation of a pilot testing report.

After an evaluation process, which included site visits, PROCESS selected a U.S. company to provide pilot facilities and operations personnel for the testing. Prior to the initial pilot plant runs, PROCESS prepared a testing plan that detailed the testing goals and the test procedure to be followed. The goals for the testing included the following:

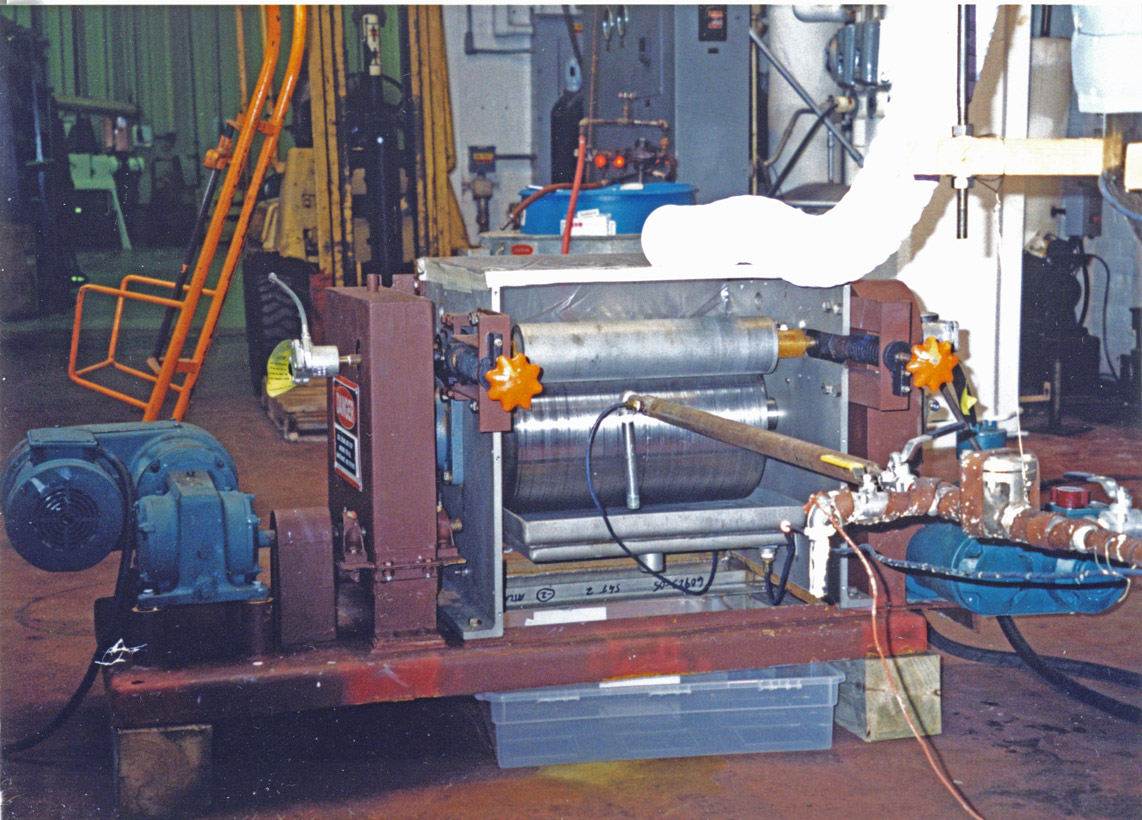

- Demonstrate the ability to produce 71% NaHS flake from 41% NaHS liquor using a falling film evaporator to concentrate the 41% liquor to 71% molten NaHS and a drum flaker to freeze the 71% molten NaHS to produce the 71% flake product

- Determine the evaporator and flaker operating conditions required to produce the 71% flake product

- Generate the data necessary for executing design of the commercial-scale evaporator and flaker for the antimony refining application

The initial pilot plant test utilized 100 psig steam as the heating medium for the evaporator, which was operated at atmospheric pressure. It became apparent during the test that the steam temperature was insufficient to drive the evaporation process to the desired 71% endpoint. The system was then redesigned and reconfigured to use hot oil as the heating medium for the evaporator for the second test. Flake product was successfully made during this test. For the final test, a vacuum system was added to the evaporation operation and the system run at a lower pressure (100 mm Hg) to demonstrate an evaporation temperature conducive for the use of 100 psig steam as the heating medium. Flake product was successfully made during this test as well.

PROCESS then summarized the results of the testing in a report that also included recommendations relative to the design of the commercial-scale evaporation and flaking operations. It is anticipated that PROCESS will execute a full process design of the evaporation and flaking operations should the client elect to produce 71% NaHS flake product.

It is noted that, without the pilot testing results, it is likely that the commercial-scale evaporator would have been designed to operate at the conditions utilized during the first pilot test. Had this been done, the NaHS production system would have required a major retrofit during startup, a situation that would caused significant delays in antimony refining production.

Industry Type

- Minerals & Metals Refining

Utilized Skills

- Pilot plant test plan preparation

- Pilot plant test plan management

- Product evaluation

- Pilot plant to commercial size scale-up

- Evaporation and flaking operations evaluation

- Waste minimization process design