Jackson Udy, PE

Recently I saw a safety article that resonated with me. The topic, Trusting Plant Instruments.

Few days go by where myself or a coworker don’t question an instrument reading at the plant I work at. And how could you not? Everyday, process engineers and operations personnel are looking at dozens or hundreds of instrument outputs. And every so often, we come across a reading that doesn’t make sense. But how operation personnel respond to an instrument that “doesn’t make sense” can have serious process safety implications.

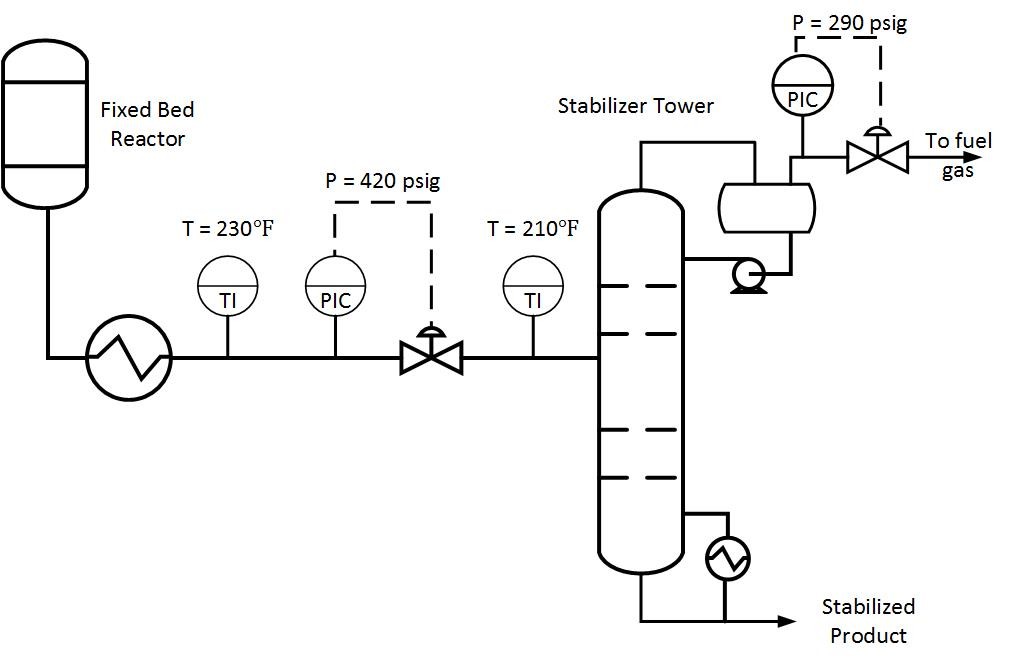

I had an experience that made this principle quite clear to me. The process flow diagram below shows the process I was working with.

I was helping with the start up of a new bypass around an exchanger. We were monitoring the feed temperature to the stabilizer tower. If the stabilizer feed temperature got too high, liquid traffic in the stripping section of the tower would be reduced, and stripping efficiency would suffer. Our goal was to keep the feed temperature at the design value of 215 deg F.

As shown above, the unit described above has two feed temperature indications. But one was reading above the design value, and one was below. So then, which one is correct? Both values can not be correct, as there is no heat exchange occurring between the temperature indications.

I looked through the process graphics and trends, self-assured that I would determine which instrument was faulty. But in my search to justify my own assumptions, I realized something unexpected, both instruments were correct.

How can this be? Well dear reader, if you study the process flow diagram above, you will notice a control valve between the two thermocouples. A small portion of the stream flashed as it flowed through the control valve, cooling the stream before it entered the tower. Indeed, both thermocouples were correct!

So why am I telling this story? I believe it teaches a valuable concept. I didn’t understand how both instruments could be correct, so I immediately assumed one reading was false. This is the wrong way to think about instrument readings. When plant personnel ignore instrumentation, it is often because we don’t understand how the reading is possible. We then discard the reading as erroneous to justify our own notions of what is occurring inside our processes. This can lead to serious process safety implications, as the two examples below show.

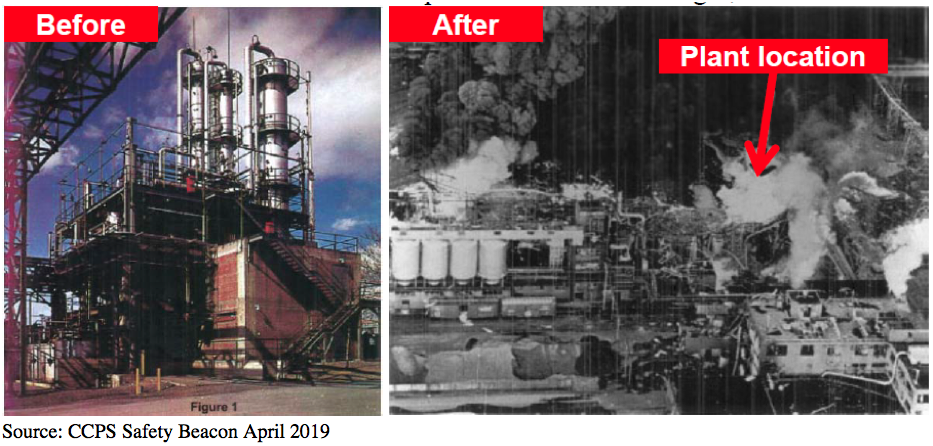

In the 1960’s, a fire and explosion occurred chemical plant in Tennessee during a unit start-up (1). a thermocouple inside a distillation column was reading 250 degrees when it “should have” read 215 degrees. An instrument technician was sent into the unit to troubleshoot the instrument just before the explosion. A post-incident investigation revealed that the high temperature readings were consistent with increased Nitrobenzene content on that tray, likely due to tray damage. Had plant personnel not ignored this information, the incident may have been avoided.

Before and after of a Tennessee chemical plant fire

Another incident occurred in the 1990’s at a California Oil Refinery (2). A hydrocracker reactor outlet temperature went off-scale high, indicating a run away reaction. The control board operator was hesitant to believe the temperature reading, and did not depressure the reactor to stop the reaction. The ensuing fire and explosion resulted in one fatality and 46 injuries.

Not trusting process instrumentation can lead serious incidents. This is especially true for instruments that indicate an unsafe condition. So what can you do to make sure this doesn’t happen to you?

- Assume an instrument is working until proven otherwise, especially when the reading could indicate an unsafe process condition. Ask yourself, What are the consequences if this instrument is reading correctly? Then take appropriate action.

- Use other instruments and samples to confirm suspicious readings.

- And finally, don’t assume an instrument isn’t working because you don’t understand how the reading could be correct!

Sources

Center for Chemical Process Safety April 2019 Safety Beacon

EPA Chemical Accident Investigation Report Tosco Avon Refinery, Martinez, California